The presence of various gases, liquids, and dust in the amount and time that will disturb the ecological balance is called air pollution. Besides, greenhouse gases released into the atmosphere cause global warming, in other words, climate change.

Among the largest sources of pollutants are warming, motor vehicles, and industry.

Major pollutants emitted to the atmosphere as emissions from the industry; “Waste gas”, “dust” and “odor”.

In line with the “Control of Industrial Air Pollution” and “Control of Emissions Causing Odor” regulations, emissions from factories and treatment plants must be reduced to below limit values before discharging into the atmosphere.

Systems are divided into three, physical, chemical, and biological. Process selection is made according to needs and operating conditions. Some of the systems applied in this context are as follows so that the emission is realized under the desired conditions (below the discharge limit level) with the purification of the pollutant gas source (TOC / VOC treatment), odor removal and dust filtration.

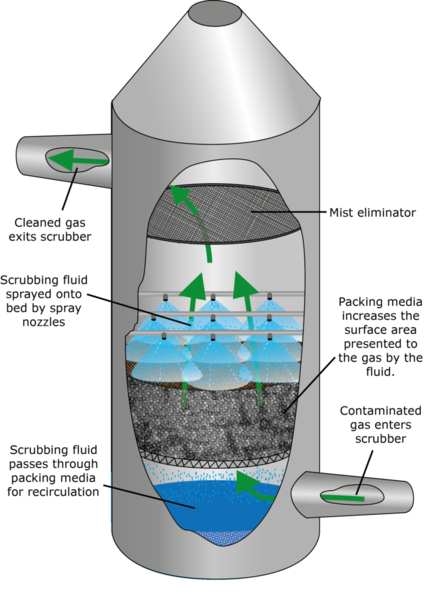

Scrubber / Chemical Gas Washing Systems

It is the most widely used system in air pollution control and has many different designs according to the characteristics of the raw waste gas. It is a highly efficient and easy to operate system used for waste gas treatment and odor removal in different areas of use.

Adsorption / Mineral (Activated Carbon, Zeolite, etc.) Filter

It is a system of reducing the pollutants (TOC / VOC, etc.) within the emission below the limits by keeping them in the filter bed by physical methods and purifying them. In this context, different filter types are used according to their pollutant properties (density, flow rate, etc.). The most common of these are “Activated Carbon and Zeolite”.

UV/Ozone

Special UV lamps ensure that the oxygen in the atmosphere is converted to ozone, and the pollutant source is directed to this ozonation system. It is a technology with low operating costs and high efficiency and plays an active role in both odor removal and TOC / VOC treatment.

Jet Pulse Filter

It is the process of removing the dust, odor, and smoke generated during the process by extracting them from the source by means of a fan, etc. systems and releasing them to the atmosphere by filtering. Different bag types can be used according to the type of air pollution, flow rate, and the characteristics of the environment.